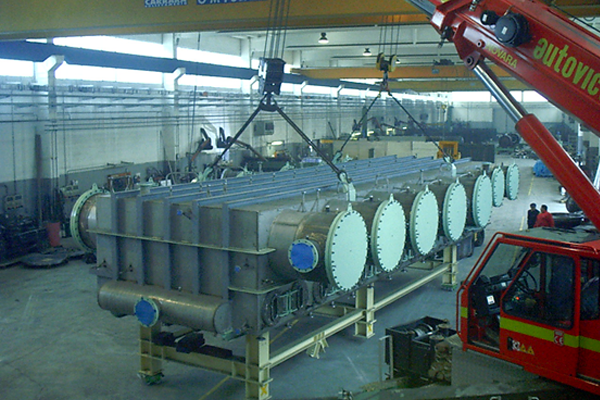

[ Pressure equipment shop ]

As part of Unidro scheme of Vertical Integration intended to provide quality and value to our customers, we manufacture our engineered pressure equipment in our own facility.

Located 20 km away from Milano and from Unidro Head Office, the features and the equipment of the workshop, the professional capability and record of the personnel, the qualifications and the certifications the company can boost place our production in the high range of the market for industrial pressure equipment.

Quality

- UNI EN ISO 9001:2008

- ASME U-STAMP

- NATIONAL BOARD

- Welded Pressure Vessels Class 1, Class 2.1

- Welding Procedures Record Qualifications (according to EN and ASME)

- Welding Operator Qualification

Some numbers

- covered area 3,000 m2

- uncovered area 2,000 m2

- Vessel diameter 4.5 mt

- Vessel length 25 mt

- Weight 70 tons (with additional cranes)

- Welding capacity 200mm

What we do

- Heat exchangers of different type and material of construction

- Vacuum degasifiers, ejectors and vacuum groups

- Phase separators, Flash Drums

- Thermal deaerators, , strippers

- Vane Separator, Cyclone Separator, Wire Mesh Separator

- Cartridge Filter, Basket Filter

- Carbon Canisters

- Direct & Indirect Heaters

- Reboiler Combustion Chamber