[ O&G Process Equipment ]

Unidro is able to provide a wide range of WELLHEAD EQUIPMENT for the Offshore/Onshore Oil&Gas Industry, including:

- Multiphase Separators READ MORE

- Desalting/Dehydrator Units

- Flash Drums

- S&T Heat Exchangers

Integrated Design

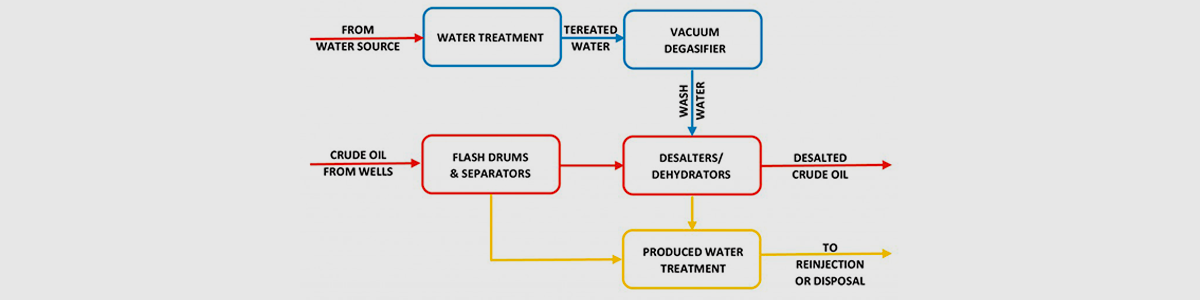

Thanks to the company experience gained over the years in both Crude Oil Treatment and Water Treatment, Unidro can now provide and Integrated Design, covering several unit operations in upstream area, including wash water deoxygenation with Vacuum Degasifier and Produced Water Treatment.

Desalter/Dehydrator

Our specialists can deal with the best available technologies such as:

- Alternating Current (AC) field

- AC high frequency field

- Direct Current (DC) field

- Combination of AC/DC field

All the components, such as HV Transformer, Electrostatic Grid, Mixing Valve, instrumentation as well as piping, pumps and Emulsion Breaker Injection Unit can be designed and provided.

Vessels manufacturing and skid assembly, when required, can be completely realized in our shop, in full compliance with the project specifications.

Flash Drums and Separators

Unidro has a wide experience in applying phase separation technologies to the water, oil and gas streams. Our process team can size the separation units using the appropriate engineering design software, including CFD, and select the best internals, either based on our in-house design or procured from the most reputable international manufacturers of separation and mass transfer components.

In all cases, the fabrication of the equipment in our ASME certified shop under our direct responsibility ensures to our products the best quality in terms of both process performance and mechanical workmanship.

Shell & Tube Heat Exchanger

Unidro can design and manufacture a wide range of shell and tube heat exchangers from the simplest up to the most critical duties.

Engineering services include thermal and mechanical design, ASME code calculations, wind load analysis, seismic analysis, fatigue analysis, shell stress due to applied nozzles and external loads and CAD drawings.

Each heat exchanger is customized to comply with the Client specifications. Design and fabrication standards comprise ASME Sec. VIII Div. 1, ASME U-stamp, PED (97/23/EC), TEMA C, B and R, sour and lethal service requirements.