[ Precoat Filters ]

The Process Principle

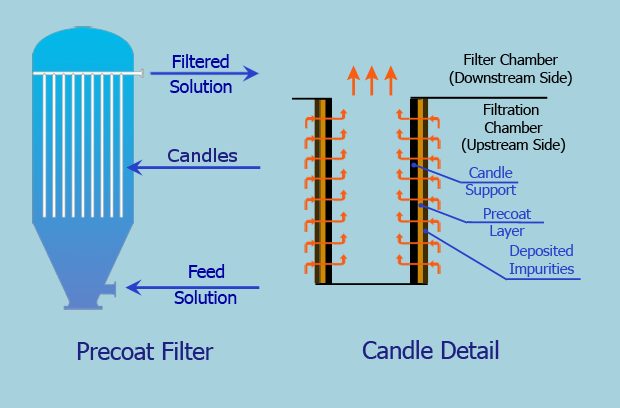

Precoat filtration is used in order to prevent filter elements from clogging and to secure fine filtration efficiency. Filter elements are protected by depositing on their surface a layer of precoat material (normally cellulose, diatomaceous earth, or similar), prior to filtration. For this purpose, precoat slurry is introduced into the filter vessel prior to start the filtration process.

Generally precoat filtration is used in the treatment of lean amines slip streams, saturated brine for chloralkali plants and turbine condensate return streams.

Precoat Filters – Candle Type

The Unidro candles precoat filters consist of a vertical cylindrical vessel with conical bottom, with filtering candles fixed at their top on horizontal nozzle sheet or collecting manifolds.

The backwash procedure may be different for each application and project requirements. The Unidro systems can be designed for slurry discharge or dry discharge, the latter involving a drying gas stream which allows delivering a dry cake for disposal.

Precoat Filters – Leaves Type

The Unidro leaves precoat filters consist of a horizontal cylindrical vessel, equipped with circular filtering leaves installed on a central internal collecting header.

The filtering elements are vertical round leaves, which can filter inward through each side. They are hold by a central shaft, which also acts as filtered liquid collector.

When the washing procedure starts, the shaft rotates the filtering leaves. A strong blade jet on the rotating filtering leaves cleans them effectively.